The BDJ-10B bonding unit consists of a hot mixer, hot water tank, water system, and electrical control system. It is controlled by PLC and operated via a touchscreen. This unit is widely used for bonding thermal mixing of metallic pigments such as flash silver, pearlescent, and floating silver with resin-based powders. The heating method for thermal mixing includes self-friction heating and auxiliary hot water heating. The glass transition temperature can be manually set, and the viscosity is automatically detected.

Consulting

Consulting

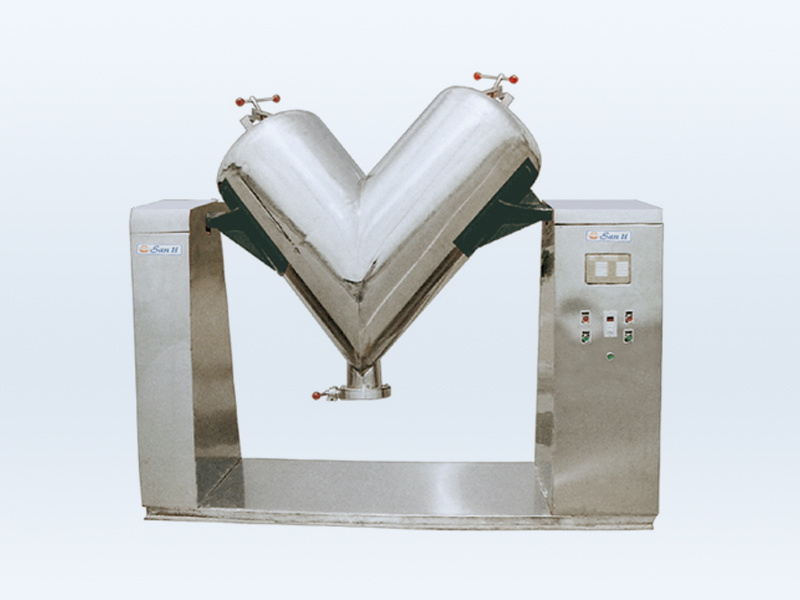

The Cone V-Series Mixer integrates both mixing and dispersing functions,ensuring thorough mixing with no dead angles. The cone body is made entirely of stainless steel and features mechanical seals to prevent powder leakage and solidification. It is easy to clean, maintains a low temperature rise, and is the best equipment for producing hybrid and artistic powder coatings.

Consulting

Consulting

XZJ Series of Double Cone Mixers

The XZJ Series Twin Cone Mixer is an ideal for pre-mixing powder coating or other product.

Consulting

Consulting

The PHJ series high-speed automatic mixers are designed for mixing multi-component granular or block solid materials. These machines can crush materials while mixing, using an advanced sealing design to prevent dust leakage.

Consulting

Consulting

The FZJ series automatic mixer features a movable hopper. When the hopper, filled with raw materials, is pushed into the basic mixing position, it is lifted to the mixing head via the automatic control system and secured by electric clamps, which are safer and more reliable than pneumatic clamps. The container then starts to rotate, mixing the materials during the swiveling process. Once the mixing process is complete, the container automatically returns to its original position. The entire operation is controlled by a programmable logic controller (PLC), ensuring uniform mixing, high production efficiency, and preventing the formation of solidified particles.

Consulting

Consulting

BDJ series bonding mixer is the whole process of heating and bonding metal pigments and powder coatings to the surface of powder particles to form metal powder coatings. Bonding metal powder has extremely bright metal luster effect, and excellent product quality is also the fastest return for customers.

Consulting

Consulting

ZDJ Series Single-Screw Reciprocating Damping Extruder

The ZDJ series single-screw reciprocating damper extruder is a versatile, high-performance mixing system designed for powder coating production. It is also suitable for the fine mixing and dispersion of other products. The screw performs a composite motion of high-speed rotation and reciprocation, ensuring that the material is fully sheared and kneaded to achieve exceptional homogeneity and dispersion. This makes it ideal for manufacturing high-performance powder coatings and other products.

Consulting

Consulting

GSJ Series Twin-Screw Extruder

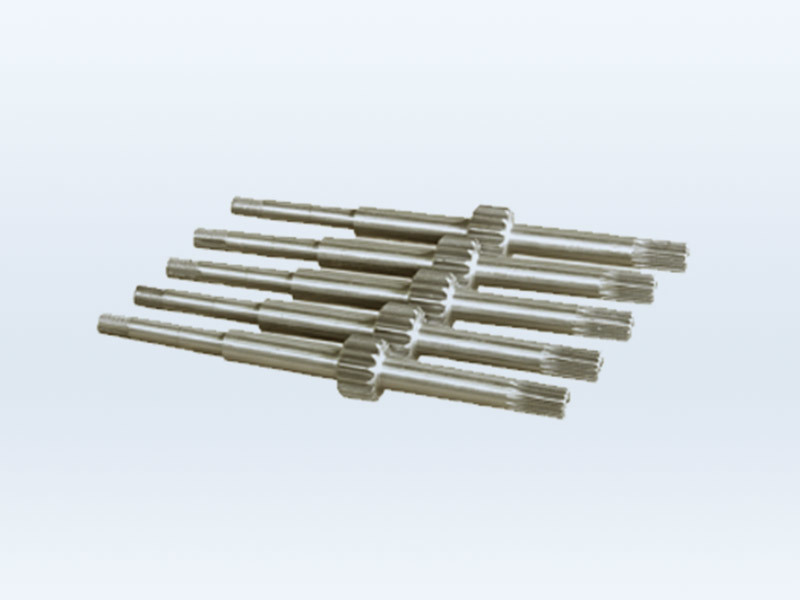

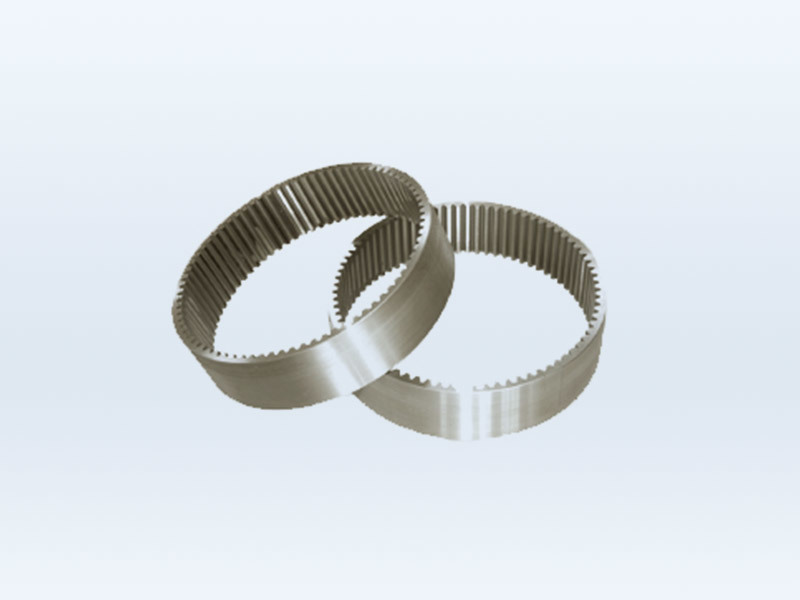

The technical performance of the GSJ-G series of high-speed gapless twin-screw extruders has been comprehensively improved. The mechanical index of the gear box is stronger than the torque power, and the reliability is higher. It ensures that the conveying section and the mixing block have smaller gaps, high precision and long service life.

Consulting

Consulting

FLP Series Stainless Steel Belt Cooling Flaker

The FLP Series Steel Belt Flaker consists of chill rollers, a stainless steel conveyor belt and drive system, first- and second-stage crushing rollers, a base frame, and an independent cooling water system. The molten material is pressed into thin flakes (1–2 mm) by the chill rollers, then conveyed on the belt to the crushing section for twostage size reduction. The flakes are rapidly cooled by multiple water spray nozzles positioned beneath the belt.

Consulting

Consulting

FYP series air-cooled tablet machine, hot State materials extruded by extruder are rolled into 1-2mm thick ribbon through tabletting roller. The tablet rolls are cooled by cooling water. During The conveying process, the materials are continuously cooled to solid state by purifying dry cold air, and the materials broken into sheets fall into the hopper. Note: coolant-temperature should be ≤ 15 ℃.

Consulting

Consulting

ACM Series Air Classifier Mill

The technical performance of the ACM series grinding mill system has been comprehensively improved. The low-noise grinding system operates at ≤85 decibels, and the temperature of the grinding body is greatly reduced with a dual air duct design. By adjusting the system parameters, an ideal and stable particle size distribution can be achieved. This system also features excellent explosion-proof equipment and anti-explosion performance.

Consulting

Consulting

The GSJ series is a complete set of laboratory equipment including mixer, extruder, cooling belt and mill. It is mainly used for producing powder samples and small batch powder coatings production lines. This equipment helps obtain high-quality formulations and process parameters for powder coatings manufacturing, accurately and truly demonstrating the formulation effects, and providing excellent conditions for small batch powder coatings production.

Consulting

Consulting

It is primarily used for process and parameter experiments of powder products, providing powder samples as reference for mass production. The equipment incorporates new technologies in the grinding process, mechanical transmission structure, and control system.

Consulting

Consulting

Get a Free Consultancy

Committed to providing energy-saving, intelligent, clean, safe and efficient high quality powder equipment production line for the powder industry.

2-2, Sanli Road, Muping District, Yantai

Shandong, China

Cellphone: +86 176 1618 8999

WhatsApp: +86 132 0535 2071,+852 5634 4039

Email: wh.powder@outlook.com, info@wanhengpowder.com

Copyright© Yantai Wanheng